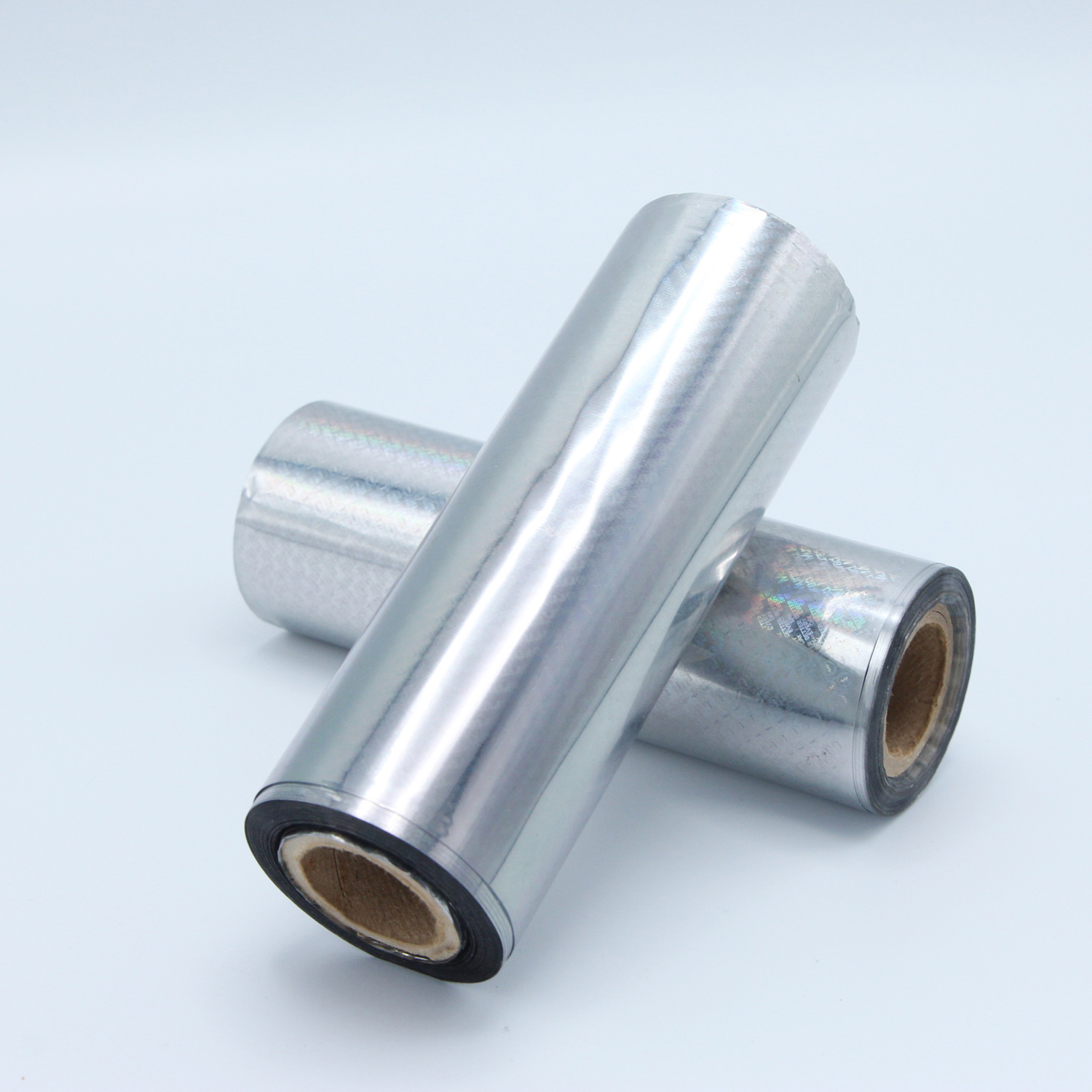

What should be paid attention to in PET film printing and dry lamination

PET film is a polar film with 45-50dyn surface tension without treatment. It is also a film with good firmness no matter what type of plastic ink is printed on it. However, after being coated with two-component polyurethane adhesive and dry compounded with other films, especially with PE film, sometimes the printing ink layer is glued from the PET film and delaminates (especially for thicker PE film). That is, the printing ink layer on the PET film is partially or completely transferred to the inner film after being compounded. So, what is the reason? What is the way to avoid it?

Because PET film has excellent barrier property and strong anti leakage property, it is difficult for solvent to penetrate, and the solvent absorption property is worse than that of ink. The binder (resin) of plastic surface printing ink has good affinity with PET film, so the fastness of printing on PET film is higher than that of plastic composite inner printing ink. In fact, the ink layer transfer of the printed PET film after lamination has nothing to do with the use of surface printing ink. Instead, the ink transfer is more likely to occur when the composite inner printing ink is used.

Attention shall be paid to PET film printing and dry lamination:

1. The ink shall be as little as possible, and the ink shall be completely dry (dry) to prevent false drying of the ink (especially when using chlorinated polypropylene composite plastic ink for printing). If the printing speed of the printing machine cannot be opened, and the drying box is not effective, the printed matter can be rolled back once, and blown or left for some time during the rewinding, and then compounded after the ink has hardened (after printing, it is better to lay aside and blow to prevent the printing film from sticking).

2. The amount of glue must be small when compounding, and the solvent of the compound glue should be volatilized as much as possible when passing through the drying tunnel (it is necessary to frequently check whether the exhaust system of the drying tunnel is unblocked, and the temperature of the compound hot drum of the recombiner should not be lower than 70 ℃.

Address:A2110, Tianrun Building, Dongfeng Street And Jinma Road, High-Tech Zone

Address:A2110, Tianrun Building, Dongfeng Street And Jinma Road, High-Tech Zone

Mobile:+8615169643109

Mobile:+8615169643109

Phone:+8615169643109

Phone:+8615169643109

Whatsapp:+8615169643109

Whatsapp:+8615169643109

Wechat:15169643109

Wechat:15169643109